KOCH SBD-B DOUBLE-END FEED-THROUGH TRIM, BORE, GLUE, & DOWEL MACHINE

Specifications

| Condition | Used |

| Stock Number | H-2118 |

Description

KOCH SBD-B FEED-THROUGH DOUBLE-END TRIM, BORE & DOWEL MACHINE

S/N:A-0507/7251, (2005 - Reconditioned by Koch in 2022), (460/60/3 electrics) H-2118

General Specifications, (to be verified):

- Approx. 25 working cycles per minute production capacity

- 0.6" to 1.18", (15 - 30 mm) workpiece thickness capacity

- 0.9" to 9.8", (23 - 250 mm) hopper workpiece width capacity

- 4.7" to 98.4", (120 - 2,500 mm) workpiece length capacity

- 36.2", (920 mm) working pass-line height

- Automatic hopper feed with hydraulic stock feed beam and automatic return conveyor to operator

- Each side equipped with trim saw units, boring units with horizontal and vertical drilling & dowel insertion

- Motorized opening with digital setting

- Linear path control for stock transport with low profile machine bed and linear guides, (fixed workpiece stops)

- Adjustable working stations with manual & motorized adjustments

Trim Saw Stations, (each side):

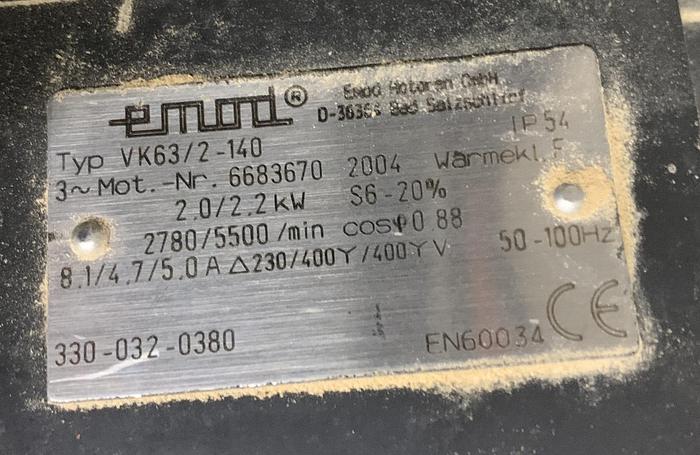

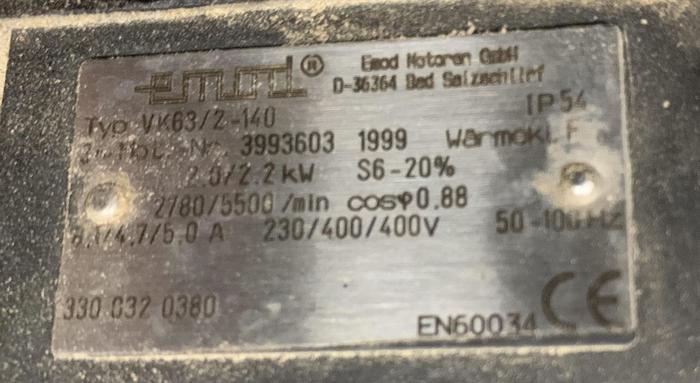

- (1) 5 HP, (2- 4 KW), 5,800 RPM saw units

Horizontal Drilling Stations, (each side):

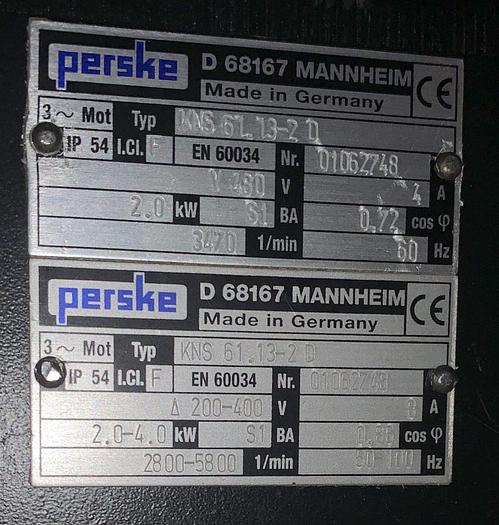

- (1) 2.7 HP, (2 KW), 3,400 RPM boring units

- Each horizontal boring unit has a 6-spindle 32 mm centers fixed centered drill block

- 10 mm diameter drill shank & 70 mm max drill bit length

- Each head moves on linear guides with drilling depth control, dust extractor hoods, & blow-out jets

Top Vertical Drilling Stations:

- (4) Top Vertical Boring Units with rotating device

- 2.7 HP (2 KW), variable speed from (3,000 - 6,000) RPM

- KOCH's "QC" (quick change) & rotating device system

- Each drilling chuck with mechanical digital read out for manual finite adjustment

- 10 mm diameter drill shank & 70 mm max drill bit length

- Each head moves on linear guides with, drilling depth control

- Boring units include dust extractor hoods & blow-out jets to clean holes

- Each unit is equipped with "QC" Boring blocks, (360° rotation) with lock

- Each unit I equipped with pneumatic locking & individual boring block adjustment

- Mechanical digital readouts for "X"/"Y" & “Z” axis adjustment

Dowel Stations:

- Currently setup for 7/16” diam. x 1-3/4” long dowels (11 mm dia. x 44.45 mm long dowels)

(other sizes & additional dowel injectors can be purchased from Koch at additional cost)

- (4) total dowel inserters, (2) per side with vibrating bowl dowel feeders

- Includes automatic dowel measurement, pressurized glue tank, & back-wash rinsing tank

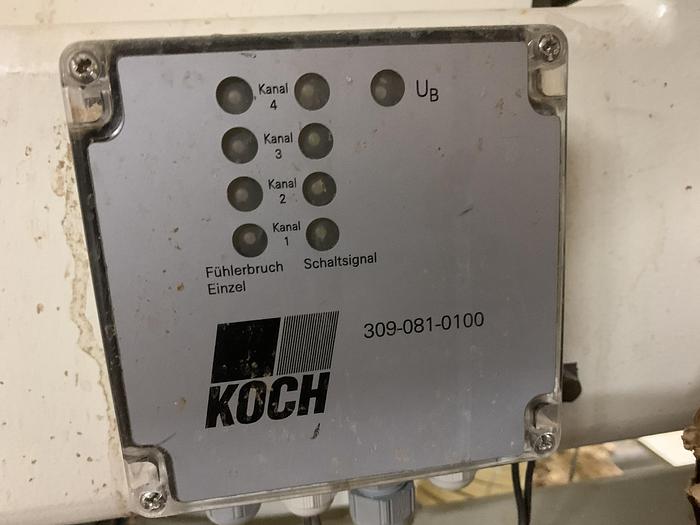

Operator & Machine Controls:

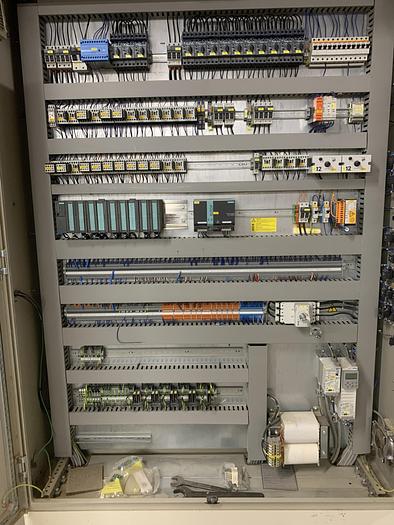

- Beckoff SPS PLC for machine function & error diagnosis

- Electrical digital setting with all drill stations arranged with readouts for "X"/"Y"/"Z" axis positioning

- The stationary machine side is on the LH side (seen in transport direction) and is not adjustable

- The RH is adjustable via motorized movement along the "X" axis

Feed System:

- Stock infeed belts move the workpiece through an intermediate hopper to the stock support

- The workpiece is transported through the working stations by means of transfer belts with lateral stock alignment

- Work pieces are automatically fed and positioned to pneumatic stops then clamped prior to trim, drilling, and/or insertion

- Last station is an aluminum table which recedes to drop workpiece to a return conveyor back to the operator

Additional Specifications:

- Open station's to add additional dowel inserting units at a later time

- Manual hand pump central lubrication system for working units

- (1) motorized right side positioning of machine “X” side, (LH side is a fixed "0' point)

- Center Stock support for long pieces

- Fixed workpiece stops

- Mechanical digital read out for manual finite adjustment

- Pneumatic material hold-down clamps

- 18' x 12' x 8' approx. overall dimensions