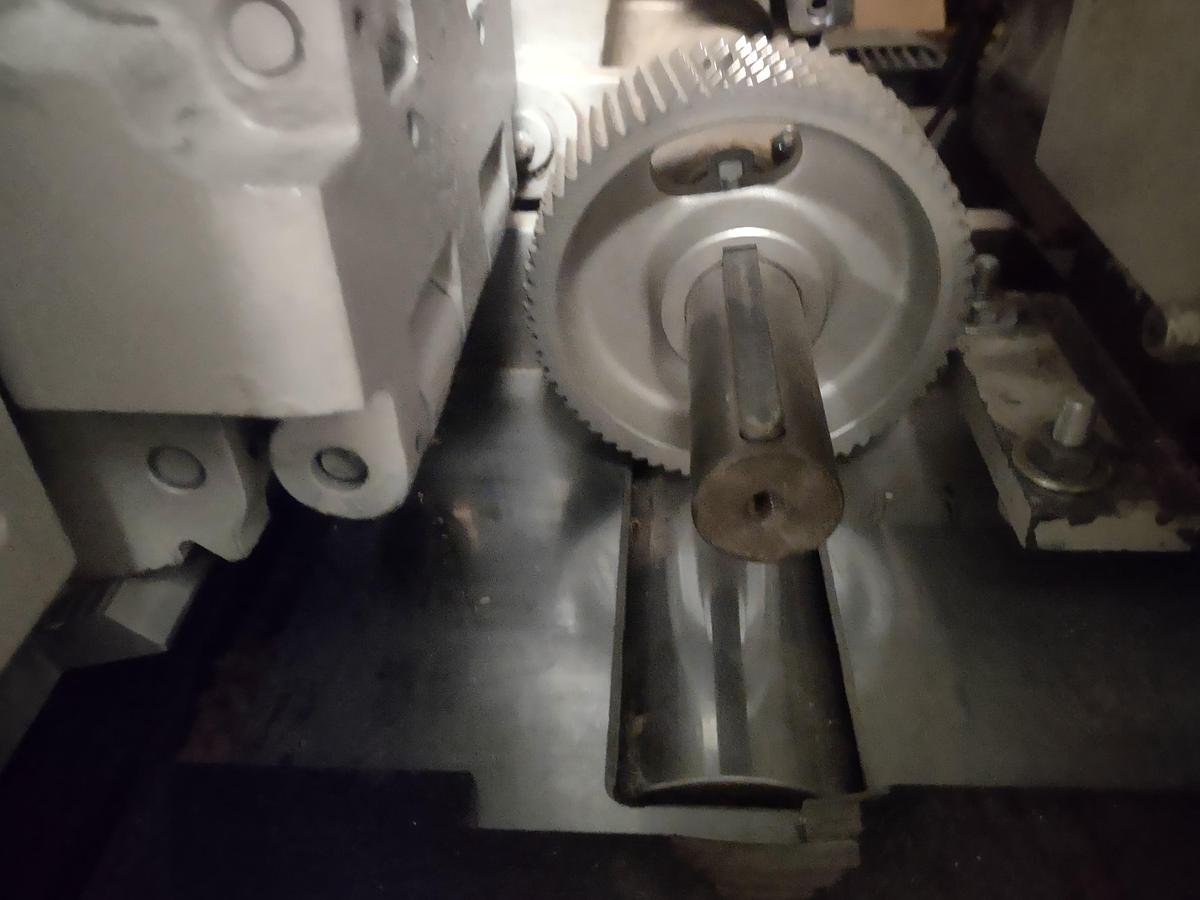

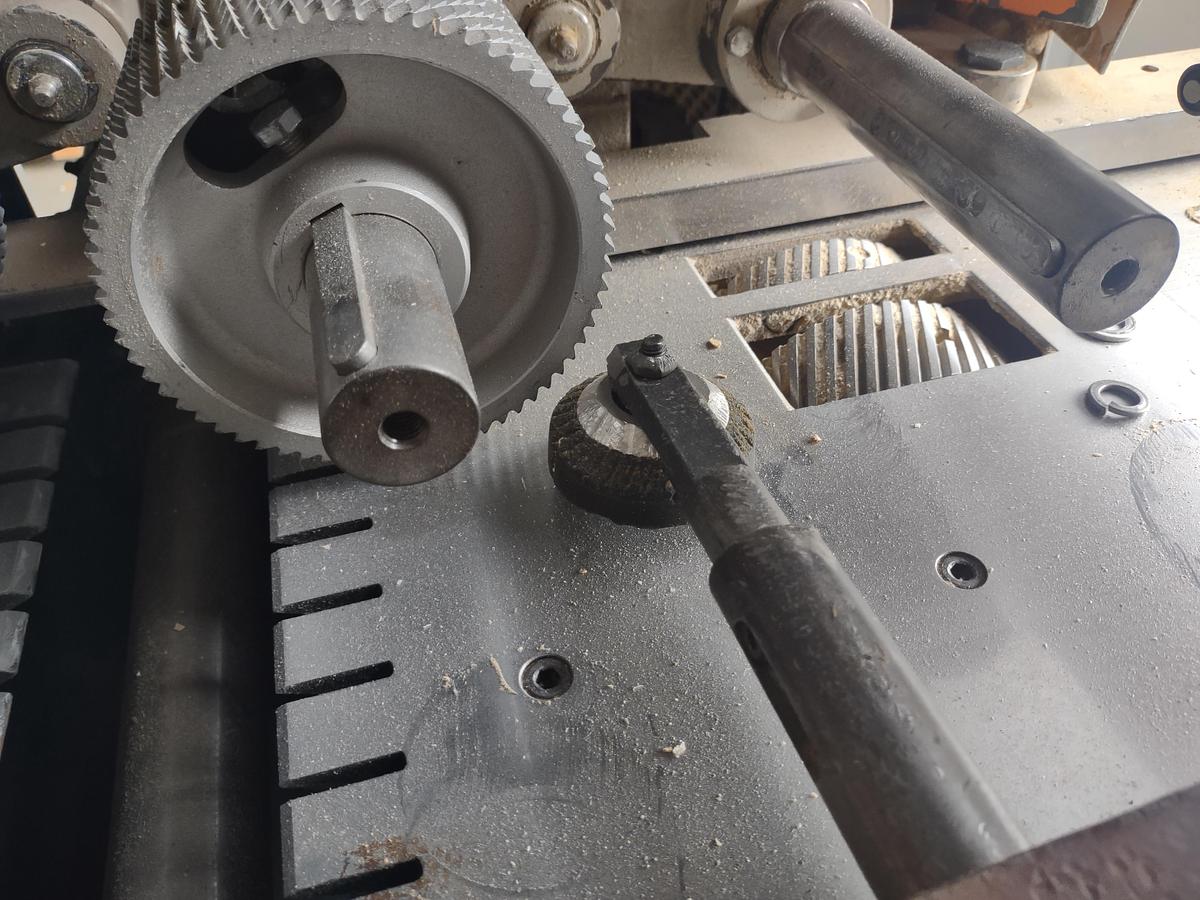

USED (GND) GN SERIES 6 X 9, 6-SPINDLE MOULDER

Specifications

| Condition | Used |

| Stock Number | H-2229 |

Description

USED (GND) GN SERIES 6 X 9, 6-SPINDLE MOULDER

H-2229

TECHNICAL DATA:

- 15 - 230 mm, 9/16 – 9” WORKING WIDTH

- 10 - 150 mm, 3/8 – 6” WORKING THICKNESS

- 1ST BOTTOM SPINDLE ALLOWABLE CUTTING CIRCLE 125 – 160 MM

- RIGHT SPINDLE ALLOWABLE CUTTING CIRCLE 112 – 200 MM

- LEFT SPINDLE ALLOWABLE CUTTING CIRCLE 112 – 200 MM

- 1st TOP SPINDLE ALLOWABLE CUTTING CIRCLE 100 – 200 MM

- 2nd TOP SPINDLE ALLOWABLE CUTTING CIRCLE` 100 – 235 MM XX

- LAST BOTTOM SPINDLE ALLOWABLE CUTTING CIRCLE 100 – 250 MM XX

- 1 HP (X2) UP & DOWN MOTOR

- 7.5HP X 1/INVERTER FEED MOTOR

- 1-13/16” SPINDLE DIAMETER

- 6000RPM SPINDLE

- 6 – 36mpm / 18 - 120fpm FEED SPEED, INFINITELY VARIABLE

SPECIAL FEATURES ON THIS MACHINE

- 45MM HIGH FENCES. CAN BE INCREASED

- SPINDLE IN/OUT ADJUSTMENT OF BOTTOM SPINDLES AT THE FRONT

- PNEUMATIC BOTTOM AND TOP INFEED ROLLERS CAN BE ADJUSTED PNUEMATICALLY BELOW OR ABOVE THE TABLE. PARTICULARLY GOOD FOR PREPLAINED LUMBER AND MATERIAL THAT IS HARD TO FEED.

- LATERAL ADJUSTMENT OF BOTH BOTTOM SPINDLES AT THE FRONT. MANY OTHER MODELS ARE AT THE REAR.

- PROGRAMMABLE ELECTRIC OILER FOR BED LUBE.

- INVERTER ELECTRIC FEED DRIVE.

- TELESCOPIC BED SURFACE PLATES FOR LARGER CUTTING CIRCLES ON BOTH SIDE HEADS. THE ADJUSTMENT IS AT THE FRONT OF THE MACHINE.

- CORRUGATED CHIP BREAKER SHOES ON THE TOP HEAD. ESSENTIAL FOR RE-ALIGNMENT WHEN LARGER CUTTING CIRCLES ARE NECESSARY.

- HIGH FENCES AFTER THE RIGHT SIDE SPINDLE FOR RUNNING STAIR RAIL, ETC.

- REMOVEABLE DUST SURROUNDINGS ON SIDE HEADS FOR EASY ACCESS TO LARGE CUTTER HEADS.

- AUXILARY OVERHEAD FEED ROLLER AT RIGHT SIDE SPINDLE. IDEAL FOR UNEVEN MATERIAL AND SHORT STOCK.

STANDARD FEATURES:

- SOUND & SAFETY ENCLOSURE. THE ENTIRE MACHINE IS COVERED TO REDUCE NOISE & PROVIDE A SAFE WORKING ENVIRONMENT.

- 0.3 mm HARD CHROME ON SURFACE TO LAST SERVING LIFE.

- OIL LUBRICATION FOR FEEDING TABLE (TO SUPPLY OIL ON THE 2 POINTS OF FEEDING TABLE WITH TIMER CONTROL)

- 1.8 METER INFEED TABLE

- ONE PIECE FULL CAST IRON BODY- HEAVY DUTY ELEMENTS MADE OF HIGH QUALITY CAST IRON WITH OPTIMIZED VIBRATION ABSORPTION CHARACTERISTICS; THE BEST FOR SMOOTH-RUNNING FEEDWORKS & SPINDLE PERFORMANCE.

- BOTH UPPER & BOTTOM FEED DRIVEN BY CARDAN UNIVERSAL JOINT DRIVE WITH NO CHAINS PROVIDE MORE ROBUST, LOW MAINTENANCE, LONGER SERVICE LIFE & GREATER ACCURACY

- EACH SPINDLE IS PROVIDED WITH A MECHANICAL DIGITAL READOUT, GIVING ACCURATE ADJUSTMENT.

- SIDE FRONT PRESSURE PLATE ON LEFT VERTICAL SPINDLE FULLY ELIMINATES UNSMOOTH PROBLEMS WHEN FEEDING SHORT OR NARROW STOCK.

- THE PRESSURE PLATE IS EASY TO ADJUST.

- CONVENIENT INFEED ADJUSTMENT; INFEED TABLE AND FENCE ARE CONVENIENTLY ADJUSTED BY THE SEPARATE CONTROL LEVERS.

- FRONT AND REAR PRESSURE PLATE: THE FRONT PRESSURE PLATE FEATURES DRAW BACK PERFORMANCE WHICH FULLY AVOIDS DAMAGE ON CUTTERS CAUSED BY AN OVERHEIGHT WORKPIECE.THE REAR PRESSURE PLATE PROVIDES EXREMELY UNIFORM HOLDING PRESSURE FOR OUTSTANDING ACCURACY OF MACHINING.

- DOCUMENTATION: MAINTENANCE MANUAL, OPERATION MANUAL, ELECTRICAL DIAGRAMS & PARTS LIST.

- 11,400 LBS: APPROXIMATE WEIGHT WITH SIX SPINDLES

- VOTAGE 460V 3PH 60C